Decoupling Membrane Matting

Decoupling Membrane Matting

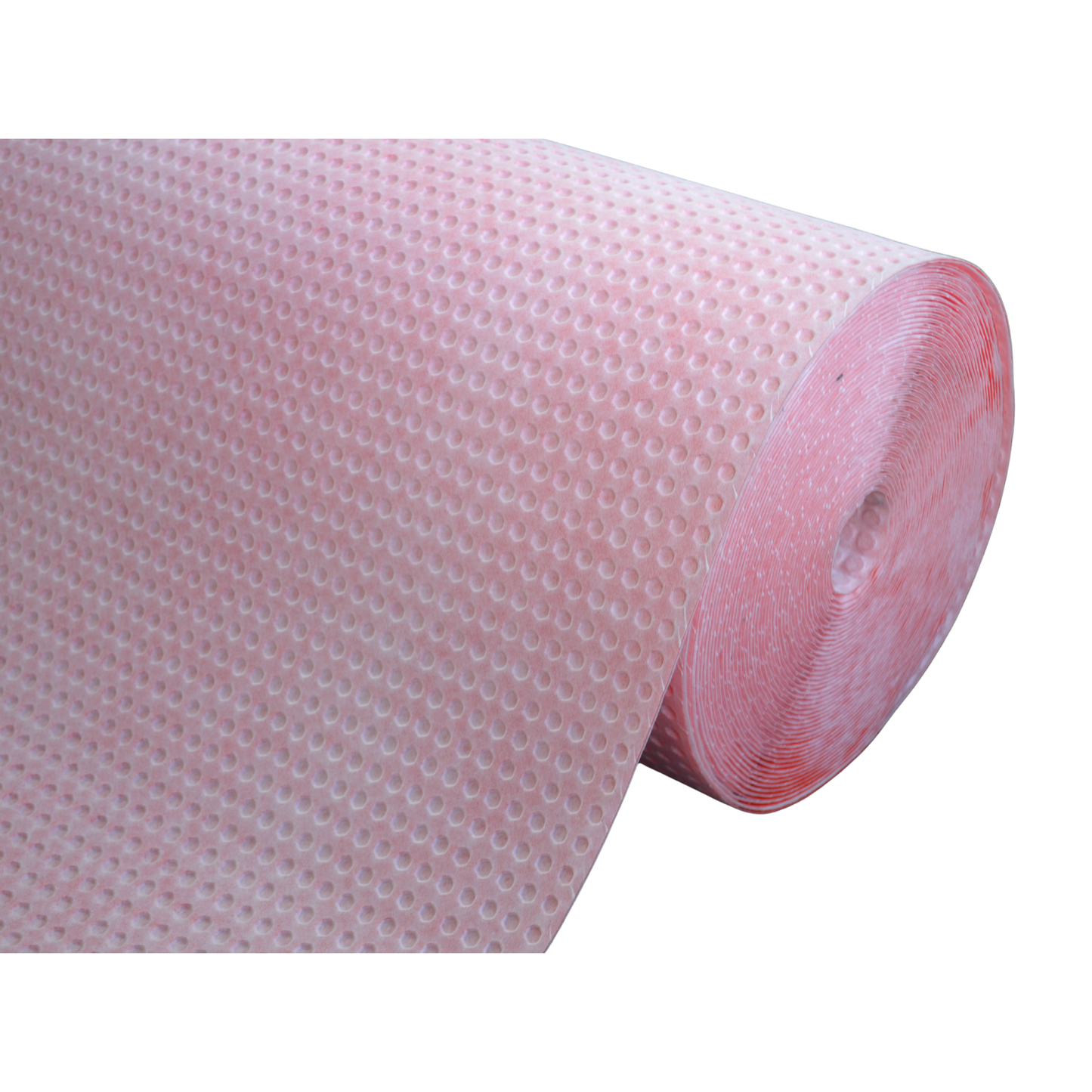

Decoupling Membrane Matting is a premium underlayment designed to prevent tile cracks caused by substrate movement, shrinkage, or expansion. Its engineered studded structure absorbs lateral stresses between the subfloor and the tile, protecting the finished surface from cracking or delamination.

Made from high-quality polypropylene with a double fleece backing, this matting is suitable for use over concrete, screed, timber, and mixed substrates. It provides excellent compatibility with underfloor heating systems and can also offer waterproofing protection when used with sealing tapes at the joints.

Lightweight, easy to cut, and quick to install, this membrane is ideal for both professional installers and DIY applications. It offers enhanced durability, improved adhesion, and exceptional mechanical performance for long-lasting tiled floors.

Key Features

- Prevents tile cracks from substrate movement

- Lightweight and easy to handle

- Suitable for use over mixed or problem substrates

- Provides waterproofing when used with sealing tapes at joints

- Compatible with underfloor heating systems

- Double fleece backing for superior adhesive grip

- Suitable for wet rooms, kitchens, and bathrooms

- Tested for Extra Heavy loads — ideal for retail, office, industrial, and public spaces

Applications

- Domestic and commercial floor tiling

- Over concrete, screed, timber, or mixed substrates

- With underfloor heating systems

- Wet rooms, kitchens, bathrooms

- Areas with potential movement or moisture

- Outdoor tiled terraces and balconies

- Renovation projects over existing floor finishes

- High-traffic areas requiring enhanced durability

Technical Specifications

| Specification | Details |

|---|---|

| Material | Polypropylene with double-sided fleece backing |

| Roll Size | 1m × 30m |

| Thickness | ~3–4 mm |

| Temperature Resistance | –40°C to +80°C |

| Water Tightness (EN 1928) | Pass – 2 kPa pressure |

| Resistance to Ageing & Chemicals | Pass |

| Tear Resistance (EN 12310-1) | Pass – > MLV |

| Joint Strength (EN 12317-2) | Pass – > MLV |

| Static Load Resistance (EN 12730) | Pass – > MLV |

| Reaction to Fire (EN 13501-1) | Class A1 |

| Load Classification | Extra Heavy – ASTM C627 (TCNA tested) |

| CE Certified | Yes |

Installation Instructions

- Ensure the substrate is clean, dry, and level.

- Apply a cement-based adhesive using a 4–6mm notched trowel.

- Lay the membrane bumpy side down into the adhesive and press firmly to remove air pockets.

- Butt sheets together and seal joints with waterproof tape if a waterproof installation is required.

- Tile directly onto the dimpled surface — the adhesive will fill the cavities, creating a strong mechanical and chemical bond.